Products

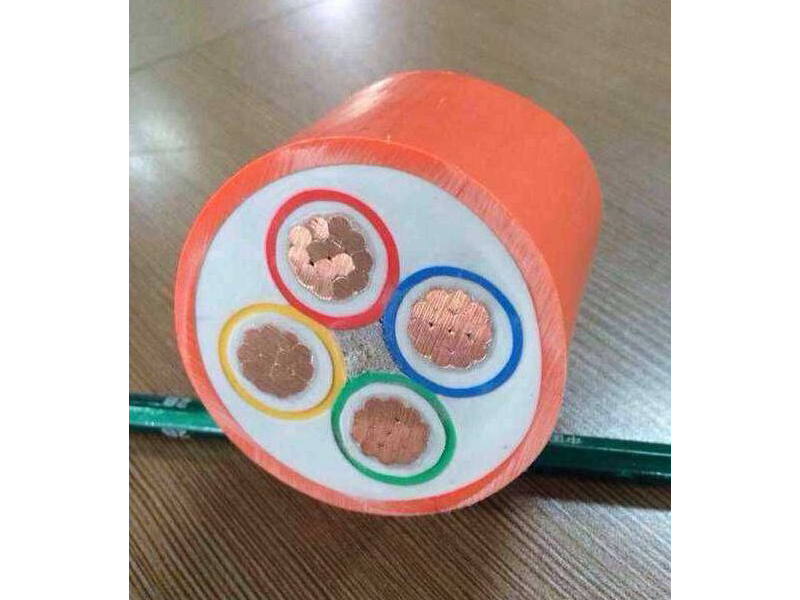

A cable with copper sheath wrapped with copper conductor core wire and magnesium oxide powder as inorganic insulating material to isolate conductor and sheath is provided. The outer layer of the cable can select appropriate sheath as required. Generally known as MICC or MI cable. There is a similar kind of cable that uses metal instead of copper sheath to wrap core wires and insulation materials. It is called Mineral insulated metal sheathed cable (MIMS Cable).

In 1896, MI cable originated in Switzerland, spread to France in 1934, and developed in Britain and the United States in 1936. Because of its excellent fire resistance, it is widely used, including BS6387, the national standard for the detection of various mineral cables, which is also the British standard. Up to here, all of them are rigid cables. After the introduction of MI cables into China, because of its high production cost restrictions, there were fewer manufacturers and users in the initial stage. Until the implementation of GB/T50016 in 2015, it was clearly required that fire lines use MI cables compulsorily, so that MI cables will usher in spring in China. [1]

According to the structure, it can be divided into rigid and flexible. According to the standard, it can be divided into national standard cable (rigid) and enterprise standard cable (flexible). Only rigid mineral cables have the old national standards. As the name implies, it is extremely difficult to bend. Transportation and installation have great limitations. Flexible mineral cables have the standards formulated by various enterprises themselves. The standards of each manufacturer vary in level and quality.

There are only six types of national standard cables: lightweight 500V BTTQ, BTTVQ, WD-BTTYQ, and heavy-duty 750V BTTZ, BTTVZ, WD-BTTYZ.

Flexible cable models are named by each manufacturer. There are more than a dozen common types, such as BTWTZ, GAN-BTGYZ, BTLY, NG-A and so on.

Article 2.0.1 of JGJ232-2011 Technical Regulations for Laying Mineral Insulated Cables states that mineral insulated cables are cables with ordinary annealed copper as conductor, dense magnesium oxide as insulating material and ordinary annealed copper or copper alloy as sheath.

The main basis for testing mineral cables in China are C (simple combustion), W (spraying), Z (impact) test in BS6387 "Fire Resistance Test Method for Cable Maintaining Line Integrity under Flame Conditions"; GB/T 19216.21 "Line Integrity Test for Cable or Optical Cable under Flame Conditions"; GB/T 13033-2007 rated voltage 750V and below mineral insulated cables and terminals".

Classification and distinction

In addition to the national standard cable (rigid), all other flexible mineral cables are enterprise standard.

Relatively speaking, the national standard cable technology is high and the construction is complex and rigorous, because the metal sheath itself is extremely difficult to bend, the installation is the most difficult, and requires expensive special accessories, fire protection performance is the highest BS6387; while the installation of flexible cable is similar to ordinary cable, the construction threshold is low, but the fire protection performance is as high as BS6387, the application is mainly based on building fire protection grade and important process. The degree selection matches the product.

Rigid mineral cables can not be produced for a long time due to technological constraints. Special accessories can be installed and used. When bending radius is installed, special tools such as roasting gun and bending runner can be used (6D). Flexible mineral cables can be produced continuously, and different metal sheath structures have different bending properties. Domestic processes mainly include copper tube (rigid), aluminum tube, transversely welded corrugated copper tube, interlocking armoured metal sheath. The bending radius is allowed to decrease in turn. The minimum bending radius is only 7D (D is the outer diameter of cables, and the bending radius of ordinary cables is about 10D). The actual site and electricity should be considered in design and construction. Restriction of cable bridge, selection of appropriate products. Generally speaking, the smaller the allowable bending radius is, the less difficult the installation is.

Rigid mineral cable itself is relatively hard, and the impact resistance is also very strong. Flexible mineral cable has strong flexibility, and its impact resistance depends on the specific structure of the cable. But all mineral cables except interlocking armored cables are difficult to lay through bending pipes, especially large size cables.

Advantage

Because all the materials of this cable are inorganic materials, it has some advantages that other cables can not have.

1. Fire Resistance

Copper and mineral insulation are inorganic materials used in mineral insulated cables. The cable will not burn, nor will it support combustion, and can continue to operate near the flame. Copper sheath melts at 1083 C.

2. High operating temperature

Mineral insulated cables can withstand continuous operation temperature up to 250 C. Moreover, in case of emergency, the cable can be operated at a temperature close to the melting point of the copper sheath for a short period of time.

3. Long life

The inorganic materials used in mineral insulated cables can ensure the stability, long service life and fire resistance of cables.

4. Explosion-proof

The highly compacted insulating material in mineral insulated cables can prevent the passage of steam, gas and flame between the equipment parts connected with the cables.

5. Small Outer Diameter

Mineral insulated cables are smaller in diameter than other cables with the same rated current.

6. Waterproof

If the mineral insulated cable is completely immersed in water, the mineral insulated cable can continue to operate with its seamless metal sheath.

7. High mechanical strength

Mineral insulated cables are durable and can withstand severe mechanical damage without damaging their electrical properties.

8. Large Carrier Flow

For cables with the same cross-section, mineral insulated cables transmit higher currents than other types of cables. At the same time, mineral insulated cables can also withstand considerable overload.

9. Rating of Short Circuit Fault

At the same temperature, the short-circuit fault rating of mineral insulated cables is obviously higher than that of other types of cables.

10. Grounding

For mineral insulated cables, independent grounding conductors are unnecessary, because the copper sheath used in this cable has played the role of grounding conductors and can provide good low grounding resistance. As far as the grounding skin protection loop (ESR) wiring is concerned, the outer copper sheath can be used as grounding and neutral conductor in the MUN system.

11. High corrosion resistance

Copper sheath of mineral insulated cable has high corrosion resistance. For most devices, it does not need to take additional protective measures. Where copper sheaths of cables are susceptible to chemical corrosion or serious industrial contamination, mineral insulated cables covered with plastic sheaths should be used.

tOP